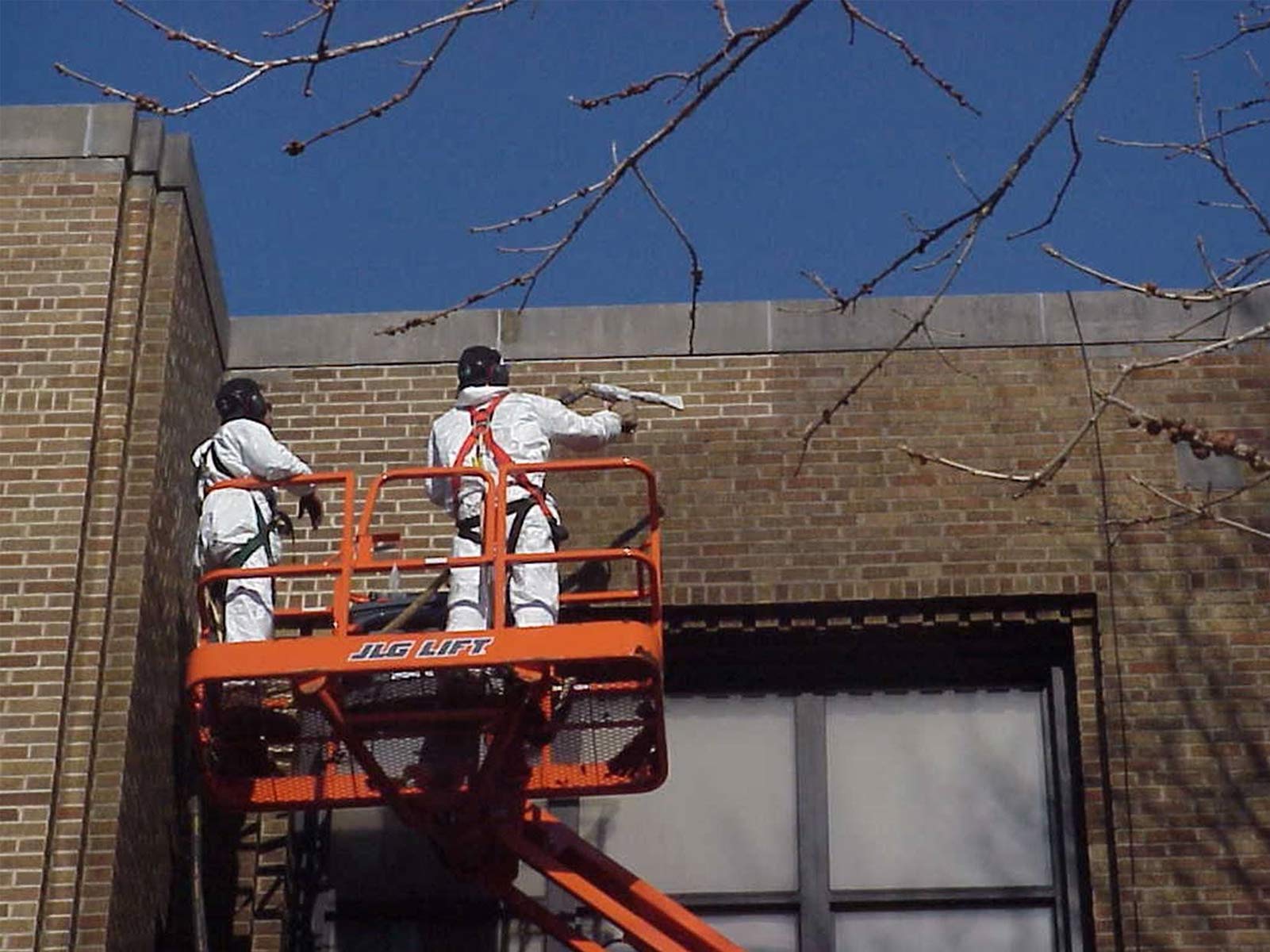

Cleaning and restoring the external facade of your business is essential for a number of reasons. It promotes a healthy and productive environment for your business, plus it also indirectly increases performance.

Dry ice blasting can be one of the best ways to do this.

Why? Because the process can provide maximum cleaning and restoration while keeping damage to zero. Even so, the process is speedy and necessarily aggressive with the dirt it has to remove.

Have you been looking for a quick, sophisticated method for cleaning your company structures? Then this may be the solution for you.

Let us explain more below.

What Is Dry Ice Blasting?

Dry Ice Blasting is precisely what it sounds like; the surface that requires cleaning is blasted with dry ice.

In the UK, dry ice is used in CO2 pellet forms. These are very soft pellets that immediately convert to vapour on impact with hard surfaces, resulting in minimal to no abrasion compared to other blasting methods.

Types Of Dry Ice Blasting

There are two types of dry ice blasting:

- double hose blasting

- single hose blasting

With the double hose method, one hose delivers compressed air while the second releases the dry ice pellets.

In contrast, a single-hose system uses only one pipe to do both jobs. As a result, the double hose system is less aggressive than a single hose.

How Does Dry Ice Blasting Work?

Dry ice blasting works in three stages:

The first stage is the initial thermal shock: As soon as the dirt or filth on the surface comes in contact with the dry ice pellets, they freeze instantly. As a result, they lose their consistency and become weak.

The second stage is the impact: The soft pellets forcefully contact the frozen contaminants. As a result, the already weakened contaminants become cracked and loose.

And thirdly, there is the expansion: No sooner do the dry ice pellets come into contact with the surface than it turns directly into vapour. This conversion from solid to vapour means a rapid exchange of heat. Consequently, there is an instant expansion of gas. Together the expansion and initial impact clear off the weak and loose debris.

All these stages take less than a second to complete!

Dry Ice Blasting Vs. Other Cleaning Methods

As well as dry ice blasting, there are other methods of removing debris and dirt from surfaces.

These include steam blasting, soda blasting and sandblasting.

While dry ice blasting is generally preferable over all these methods, it is important to consider the surface that is being cleaned as this will impact the options you have.

For instance, in Steam & Pressure Blasting, water is the main component. And when water is involved, this means the possibility of rust and corrosion. Plus, water at high speeds has the potential for a lot of damage. So steam & pressure blasting is not suitable for valuable and sensitive industrial structures.

On the other hand, Soda and Sand blasting are associated with residues. After cleaning a structure with soda and sandblasting, you will see fine particles left on it that you need to get rid of. Therefore, unlike dry ice blasting, you cannot perform this cleaning method anywhere you wish. Instead, it requires a particular facility.

What Can Dry Ice Blasting Restore, Clean & Renovate?

Dry Ice Blasting can help you clean and restore:

- brick & stone

- facades

- cladding

- buildings

- flooring

- internals

- beams

- commercial equipment

- plants and other structures

It is also very effective in getting rid of pathogens, so as a result, it is widely used to clean food processing equipment in the food industry.

Plus, being the least impactful cleaning method, it has been used in preserving and cleaning historically essential structures. Aerospace, semiconductor, and medical equipment manufacturing services use it for similar reasons.

Getting rid of sticky dirt

Degreasing or getting rid of oily and sticky dirt was one of the first intentions for using the dry ice method.

Today, it is used to clean industrial surfaces of similar substances like bitumen and tar. Sticky substances like these can easily contaminate concrete surfaces, brick walls, and storage tanks and make them grimy and gloomy.

The build-up of tar or bitumen can hamper equipment function, and this kind of dirt can be pretty stubborn. Plus, the dirt can sometimes accumulate in places that are hard to reach by hand or brush. Therefore, dry ice blasting is one of the most popular methods of cleaning these sorts of materials.

Whenever the tar or bitumen comes into contact with the dry ice pellets, they instantly freeze and lose their typical structure. As a result, they become weak and loosen from the surface, and you get clean equipment without any damage or residue from the cleaning method.

Maintenance of metallic structures

Metal is relatively abundant in industrial settings. Machines, various structures in the interior designs, and other various metal applications are commonly present. And in nearly all kinds of metallic structures, rust is inevitable.

Dry ice blasting can clean away all kinds of rust and help you restore metal equipment. No matter how long the rust has been accumulating on the surface, you can quickly and effectively clean it with this cleaning method.

The main reason metal structures degrade with time is corrosion. These structures react with the environment to create a chemically stable oxide, known as corrosion – which is why metals are damaged, and the machines lose their efficiency.

But you can successfully prevent corrosion by dry ice blasting, increasing the longevity of metallic structures.

Removal of paint

Another valuable application of dry ice blasting is removing paint from brick walls and other locations. Like dirt and filth, paint also sticks stubbornly to a surface, and dry ice blasting utilises the exact mechanism to remove it (e.g., expansion and impact) as other sticky substances.

However, unlike the other methods of removing paint, dry ice blasting doesn’t damage or scratch the surface from which it erased the paint. Instead, the paint particles fall off the surface when exposed to the CO2 pellets.

Restoring Wood

Wood is a much more organic surface than metallic structures or brick walls, which means that cleaning it requires sophisticated techniques. Plus, wood has a greater tendency to catch onto dirt and grime.

Most wood cleaning techniques tend to use chemicals to restore it. However, such chemicals can destroy the natural beauty of the wood. Plus, they are not always a hundred percent effective in getting rid of stubborn filth.

As a result, dry ice blasting has become the most preferred method of cleaning wood. You can quickly and safely clean wood with dry ice techniques, plus this method can reach the fine cracks and crevices in the wood that are otherwise impossible to clean.

Vinci Response Services: Professional Dry Ice Blasting Company

Dry ice blasting is undoubtedly the best way to keep your commercial structures clean, and help restore them. However, you must make sure you use the cleaning technology correctly. And for that, you require the services of a professional and experienced company like Vinci Response Services.

Vinci Response Services have been in the cleaning and restoration industry for over 70 years. We have satisfied numerous customers and provided cleaning solutions to all kinds of establishments within this time. IPAF, BDMA, CHAS, and many more nationally recognized accreditation prove our unwavering good service.

When you choose Vinci Response Services, you can expect fast and accurate response and solutions. We have the latest technology and experienced staff for your job – all these at competitive rates. So, get in touch with us for your dry ice blasting jobs.